Take the Next Step Toward Growth and Excellence

How We Help

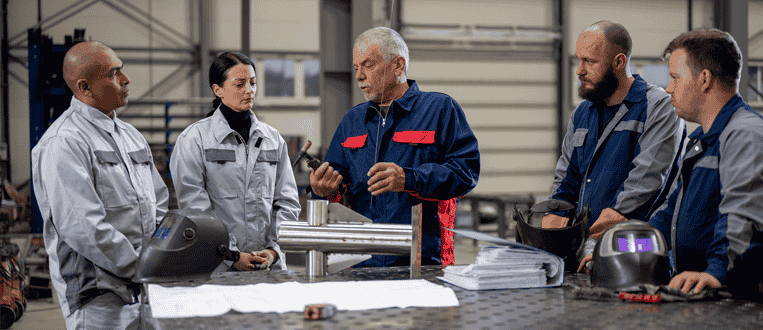

WMEP is a nonprofit consulting organization, and our mission is simple: help Wisconsin manufacturers succeed. We aren’t just consultants—we partner with small and mid-size Wisconsin manufacturers to implement lasting improvements and sustainable business growth. Our advisors bring real-world industry experience and deliver practical solutions across three key focus areas: Growth, Operations, and People.

Our Impact in Wisconsin

4,000+

Manufacturers Served

26,518

Jobs Created + Retained

$6.5b

Economic Impact

WMEP is part of the MEP National Network™, a public-private partnership that advances U.S. manufacturing.

Our Services

Growth

Manufacturing Growth, Strategy & Transformation Solutions

WMEP collaborates with Wisconsin manufacturers to build strategic growth plans, expand into new markets, and implement transformative initiatives that improve business performance.

Operations

Manufacturing Operations & Automation Solutions

WMEP partners with Wisconsin manufacturers to improve productivity, streamline processes, and integrate technology. Our customized solutions help businesses reduce costs and achieve profitability goals.

People

Talent & Culture Solutions for Manufacturers

WMEP supports Wisconsin manufacturers in identifying, attracting, and retaining skilled talent while cultivating an engaged, high-performing workforce that fuels long-term success.

Manufacturing Case Studies

From Pewaukee to the World: How ExporTech® Powered Eco Latch Systems’ Global Growth

Read more: From Pewaukee to the World: How ExporTech® Powered Eco Latch Systems’ Global GrowthCompany Profile Eco Latch Systems LLC, founded in 2010 by brothers Jack and Jim Wilson in Pewaukee, Wisconsin, designs and manufactures Box Latch™ reusable clips that close and secure corrugated boxes without tape, staples, or damage. Their innovation extends the life of cardboard boxes, helping companies reduce waste and improve sustainability. The company’s ingenuity recently…

Testimonials

Beth did an excellent job facilitating a diverse group of employees through the Value Stream Map process as it pertains to the manufacturing of brass brush holders. These holders are what contain a brush in a motor or generator. Two key results from the VSM included: a 5-day reduction in our quote lead time; and a 15% increase in weekly capacity.

Joe Miller

,Vice President OperationsHelwig Carbon Products