Manufacturers must navigate multiple challenges on the path to growing their business. For instance, balancing a higher cost of labor with chronic workforce shortages, or growing sales amidst economic uncertainties. The common denominator is that they need to do more with less. And that’s where production efficiency through automation comes in.

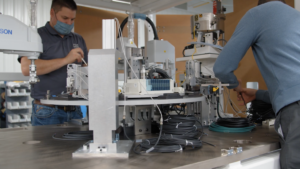

Husco is a Waukesha-based privately-owned company specializing in high-volume production of hydraulic and electro-mechanical control systems. Husco has served the automotive and off-highway industries for more than 75 years, delivering high-quality parts by the millions to each customer. To accomplish this, Husco leveraged its three essential values of intelligent risk-taking, high performance, and practical innovation to custom build its own fully automated production lines.

In 2019, Husco opened its manufacturing automation design, build, and integration services to the public by forming Husco Advanced Manufacturing Group (AMG). The Husco AMG team proudly continues to serve Husco while helping small and medium manufacturing businesses in Wisconsin solve growth challenges through automation.

Husco AMG makes its extensive experience available to enable manufacturers to save time and increase their throughput, allowing these companies to obtain higher levels of quality and performance.

“We have the distinct advantage of knowing what it is like to live with the equipment we build,” said Jason Schuetz, Vice President of Global Operations, and Advanced Manufacturing. “We are uniquely qualified to build a solution because we know it will work.”

A Holistic Approach

In a recent project, Husco AMG was challenged to increase production output for an already successful, seamlessly automated process. The customer had the business goal of increasing production capacity as a way to reduce costs.

The Husco AMG team audited the entire production line to determine why the current system could not reach the capacity goal on its own. They were able to identify four bottlenecks: a robot that had too many tasks, a gantry system that wasn’t moving fast enough even at maximum speed, an overloaded servo, and multiple obstacles in a robot’s path. Each bottleneck was handled individually with a robust automated solution.

The result was a decrease in each part’s cycle time from 7.5 second to 6.5 seconds. The one second decrease in speed meant the customer could produce the same quantity of parts in 44 weeks instead of 51 weeks. They saved $46,000 per year in labor costs – mainly from eliminating the need for operators and tech support to work overtime. Freeing up employee weekends created the additional benefit of an employee morale boost.

Piloting Through New Technologies and Techniques

Husco AMG can support small and medium manufacturers in southeastern Wisconsin with material handling, robotics, vision systems, data management, design services, equipment validation, and controls programming. The team leverages these capabilities to put automation to work through the following service offerings:

- Automation Solutions Husco AMG’s goal is to understand the project in the context of the manufacturer’s business goals, and to provide a solution that includes the level of automation that meets their unique needs.

- Test Automation Using proprietary software programming, Husco AMG can create a unique test solution for almost any application. The team can also easily incorporate other process controls into test systems, such as vision inspection, labeling, serialization, or value-added functions, such as barcode reading.

- Modernizing Equipment and Processes Manufacturers looking to get more out of their existing equipment, including automating manual processes, adding sophisticated controls, or verify processes, can work with Husco AMG to provide complete solutions.

- Service and Support Husco AMG works with manufacturers upfront to understand their existing knowledge base and how the integration solution will match technical capabilities. Once an automation solution is up and running, the team is available for service, support and maintenance as needed.

Whenever a manufacturer launches a new product, is committed to continuous improvement, needs to scale along with market demand, wants to modernize with technology, or expands its production facility, the company is entering areas that come with unknowns. Husco AMG is an experienced partner that can help manufacturers navigate and solve these challenges so they can stay on the path to long-term success.

****

Read more about the team at HuscoAMG.com