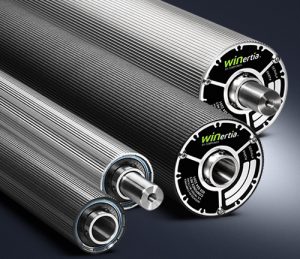

Componex, which operates a facility in Edgerton, Wisconsin, is a division of Oklahoma City, Oklahoma-based Maxcess International. Componex manufactures precision, aluminum idler rollers that have extremely low rotational inertia. Its products include WINertia idlers, which feature free spinning, low inertia rollers.

SITUATION:

WMEP Manufacturing Solutions has been doing business with Componex since 2005. The relationship started with a Lean Culture project. Because of the long history of working together, Componex turned to WMEP to assist it in writing standard operating procedures. There was significant community knowledge among the workforce and thus a lack of repeatable and predictable processes and outcomes. Componex has been hiring new employees and experiencing difficulties in transferring knowledge from experienced employees to new hires. The company needed to document processes that could be easily understood by a non-technical staff but didn’t have the resources to achieve that goal.

SOLUTIONS:

WMEP trained key employees in Training Within Industry-Job Instruction (TWI-JI). There were 30 standard operating procedures that needed documentation, but Componex didn’t have the capacity to write these in a compressed time frame, so it turned to WMEP to perform the work. WMEP used Componex’s regular standard operating procedures format but inserted the TWI-JI layout of Important Steps, Key Points and Reasons Why. Where appropriate, WMEP also documented procedures using photos embedded in the standard operating procedures to provide more clarity to the process. WMEP then had Componex verify the accuracy of the standard operating procedures and approve them.

RESULTS:

- Cost Savings – $126,000

- Plant and Equipment Investment – $110,500

- Workforce practices savings – $72,000

- Investment savings – $75,000

“It’s always a pleasure to work with WMEP. There is exceptional value in all the training we do with the organization. Our business structure is changing with our company being bought by a larger corporation. The challenges that we will have will be much more operational and geared toward greater productivity. I look forward to working with WMEP and its team more.”

Darcy Perona, Componex, Director of Operations