COMPANY PROFILE:

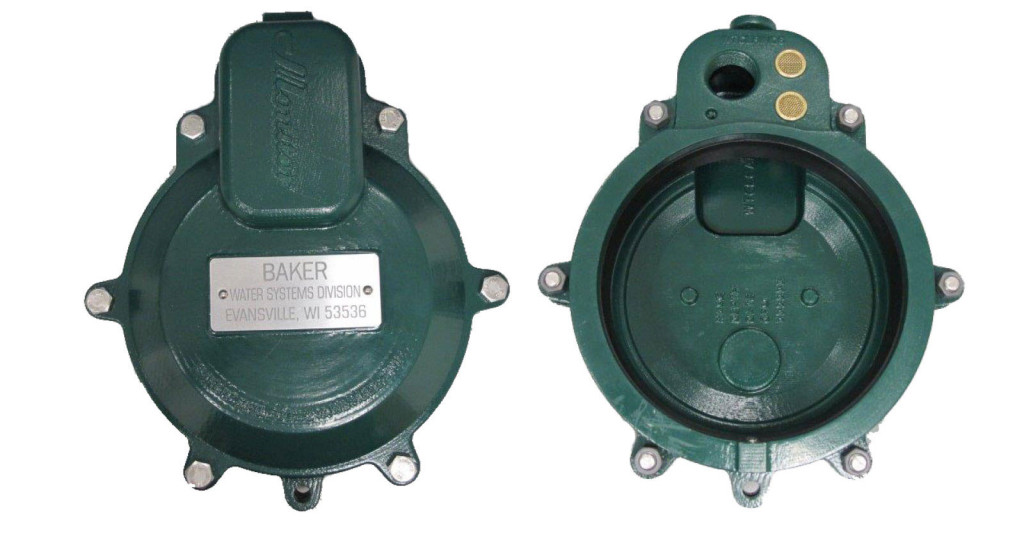

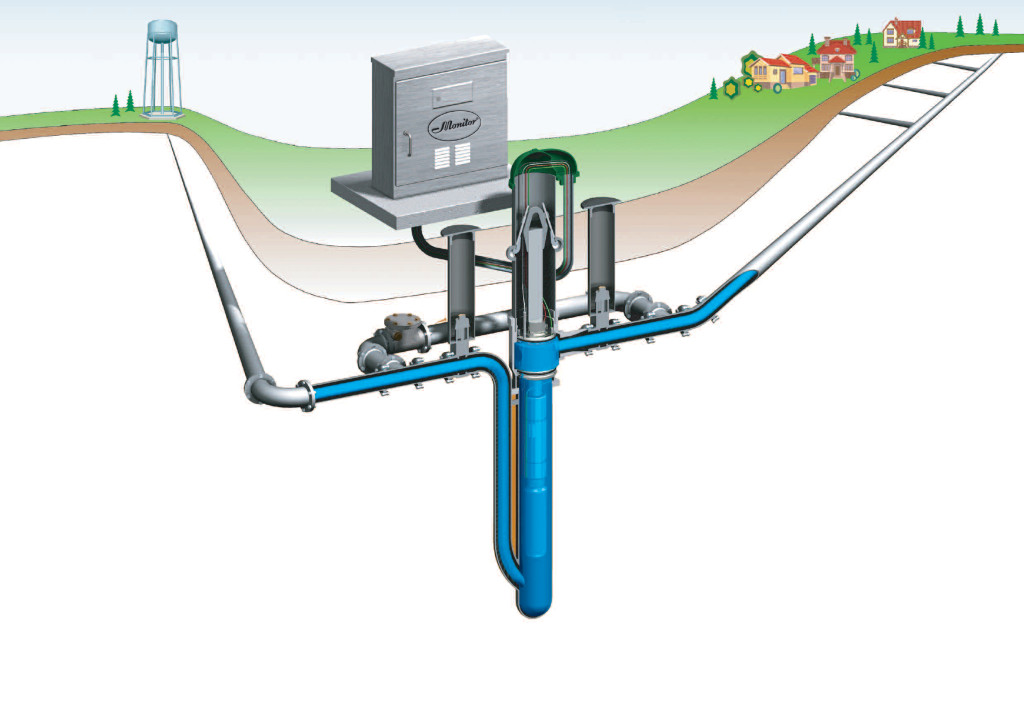

Founded in 1873, Baker Manufacturing Co. LLC is located in Evansville, Wisconsin, and consists of three divisions: Baker Casting Division; which pours gray and ductile iron castings; Haight Pump Division, which produces gear pumps; and Baker Water Systems Division, which manufactures products for residential, municipal/industrial, and environmental use. Baker Manufacturing Co. acquired Campbell Manufacturing in 2008. In all, Baker has between 100 and 200 employees.

SITUATION:

WMEP Manufacturing Solutions has been delivering successful projects at Baker Manufacturing since 2005. The latest project came about when Baker needed to increase its capacity and reduce throughput in its industrial water systems welding department to meet existing and future demand. To increase capacity, Baker needed to add another welder and rearrange the work area. To reduce throughput time, it needed to be more efficient in the welding process and reduce the waste associated with an inefficient layout. Improving throughput time and decreasing lead times created an opportunity to significantly increase sales. By reducing lead times, Baker can attract more customers and improve market share.

ACTIONS:

To develop a weld work layout area, Baker first conducted an analysis and design process that involved: creating a charter; collecting and analyzing data; developing a matrix of product families and process steps; creating a value stream map of current processes; developing future state flows using lean principles; and identifying process change requirements.

A second phase involved creating a plant layout that considered future state flows using lean principles, having the project team agree on a proposed layout and having the team report out to management. Next came the facilitation of a 5S workplace organization method.

RESULTS:

- Increased sales by 11% year over year

- Plant and equipment investment of $20,000

- Cost avoidance of unnecessary plant and equipment totaling $25,000

- Added two employees

- Reduced lead times to meet customer requirements

- More cross-trained welders

- Streamlined layout of production space

“We enlisted the help of WMEP to provide training and guidance on 5S organization to a young welding team that was facing extremely high sales order growth. WMEP came in for six sessions over the course of two months. This compressed timeline definitely energized the weld team to make the needed changes in their areas. There had been turnover with the team and this focus on organization and streamlining the area was able to bond them together to make good improvements.”

Dawn Marsh, Baker Manufacturing Operations Manager